When fiber laser cutting machine cut metal plate, it need focus one bunch of laser on very very point. Smaller focal spot size, better cutting precision, and the cutting gap is thinner. So when we select fiber laser cutting machine, we prefer to make the spot size smaller.

When we use laser machine, many factors will influence the size of focal spot size. and what is the main factor?

Main Factor for Focal Spot Size

According to the principle of laser cutting, there are three main factors influence the size of spot.

- Laser Beam Quality(M²)

- Diffraction

- Spherical aberration

Focus lens’s shape and focus length decide diffraction and spherical aberration. And laser beam quality depend on the the laser source and laser transmission system, such as the inner diameter of fiber cable.

1. Diffraction

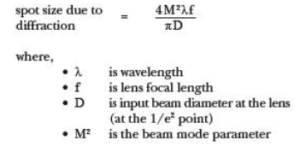

Laser light is wave, so the diffraction is inevitable. This phenomenon exists in all optical systems and can determine the theoretical limits of these systems in terms of performance. It causes the beam to propagate laterally. When focus a collimated laser beam, if we use an „ideal“ lens, the spot size will only be affected by diffraction. We can calculate the spot size with follow:

We can use it calculate the spot size come from aspherical lens.

The most important influence of diffraction is it will let spot size become big with the focus length’s increase. And it is inverse ratio with bean diameter. So if beam diameter increase, diffraction become weak and spot will become small. Also for one special laser beam, spot size will become small when focus length decrease.

2. Laser Beam Quality(M²)

Such as you saw in above formula, spot size is direct ratio relationship with beam quality(M²). M² means one special laser beam’s divergence speed in transmission. For one ideal laser beam, M²=1. Laser source supplier will offer this parameter in their technical sheet.

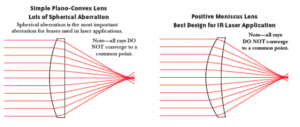

3. Spherical aberration

Spherical aberration will make spot size larger, and move the best focus to different position with what we calculated. Many different factors will influence it, such as shape of lens, orientation and refractive index.

Contact Information:

Email: xintian104@xtlaser.com

Skype: saint512406

Mobile&whatsapp : 0086 18766152065

Web: www.xtlaser.com