The application of UV laser marking machine-Ariel

The application of UV laser marking machine

This article is about the application of UV laser marking machine.

The UV laser machine is a technology very different from CO2 and Fiber laser technology.

Today we are going to explain the main differences between this technologies.

Cold laser engraving

Also knows as the blue laser beam, this technology has the capacity of engraving with a low rate of heat.

The light wave or UV light spectrum of this machine is one of the main reasons this technology can engrave over different materials.

Because it doesn’t heat the material surface as the Fiber and the CO2 does.

It allows the UV laser mark clear and with high precision over all the plastics and other materials that have an adverse reaction with heat.

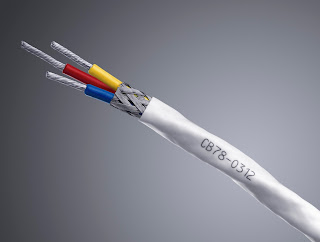

Plastics

There are thousands of different mix of plastics, and all of them can be engraved for UV laser technology.

These are some of the most common plastics engraving with our laser engraver machine.

Metals

The UV laser it can engrave and mark metals, but not always with the same effect as the fiber laser engraver machine.

While a fiber laser can etch over the metal surface with deep effect and with a clear result.

The UV laser has problems engraving metals covered with painting, or metals highly reflective like the copper.

Check below the list of metals that the UV laser can engrave.

Glass

The UV laser is one of those technologies that can engrave over glass surfaces without a break or overheat the material.

You can create amazing engravings and patterns without splinter glass result.

Contact us for more details.

Ariel Liu

Email:xintian122@xtlaser.com

whatsapp:0086 17866940010