XT LASER-providing the full sets of equipment of jewelry processing

Since ancient times, jewelry always is a woman’s heart love.

Young girls with simple atmosphere of jewelry dress show fashion. And star ladies with luxury brand jewelry accessories reflect the taste.

And now, as the development of modern technology, it fills jewelry for the future into a new impetus. Laser processing technology has got into the jewelry industry. With its high speed, high precision and convenience and popular, LASER machine has won more and more applications and gradually become an important part in jewelry business.

Laser marking – precision machining, customized model

Xintian technology fiber laser marking machine processing video on rings

Laser marking machine in the jewelry industry is mainly used in the surface of the jewelry, to mark with a fine pattern and structure. With the brightness of gold and silver, it can achieve a more perfect overall pattern. The emergence of this laser processing technology solves the drawbacks and failure rate of the traditional scissors and it is also exquisite precision. and it can be customized according to the different needs of customers, and more to a certain extent to meet customer needs.

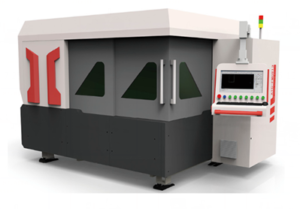

Laser cutting – metal jewelry, unlimited creation

Traditional jewelry processing mainly is based on hand-made. But with the ever-rich variety of jewelry, especially the increased popularity of metal jewelry, the traditional processing methods have been unable to meet the development of jewelry industry. At this time, laser cutting technology applications becoming popular in this situation.

Whether it is bracelet, watch, necklace, ring and other personal jewelry, or metal crafts, lamps, decorative iron and other home accessories, laser cutting technology are much faster, higher efficiency, better processing and other characteristics. It has been the first choice of jewelry processing industry

Laser welding – innovative technology to open the future

Xintian technology jewelry welding machine

Laser welding with high welding strength and speed, low scrap rate characteristics, is widely used in modern manufacturing. In the jewelry manufacturing industry, compared with the traditional welding methods, has obvious advantages.

Fast, high strength, small deformation, no orthopedic and clean after welding

Suitable for welding precision parts, to ensure the quality of the workpiece

High precision assembly, help to develop new jewelry production process

Consistency and stability

Can simplify the repair work of the workpiece

Do not pollute the environment

Can save metal materials

Contact Information:

Email: xintian109@xtlaser.com

Skype: xtlaser10

Mobil : 0086 18353156659(Whatsapp)

Web: www.xtlaser.com